False Positives in Thermography

Mazza Inspection Group / Thermograpros of Los Angeles

Full Disclosure: The use of thermography and thermal imaging is not perfect or 100% accurate. The use of thermal imaging cannot be relied upon as the sole source in substantiating an issue. Other tools are also necessary for quantitating, definitive conclusions to anomalies. False Positives in Thermography are extremely common.THERMOGRAPROS

As a Level III thermographer, I’ve taken countless (residential) images in just about every conceivable condition imaginable. In many cases, our inspections or evaluations are nondestructive from the exterior side of a building’s envelope or, the inside. Of all the conditions we encounter, I must say that destructive testing is necessary more than two-thirds of the time to confirm a condition or rule out a false positive, but is rarely performed.

The need for other tools

As a result, we rely on other different tools for measurement to confirm to the very best of our ability that an anomaly is in fact, an adverse condition. It’s my opinion that destructive testing is in most cases the only way to confirm an issue unless of course, the condition is on full display.

Air movement and infrared false positives

Air movement is by far the most common of all False Positives in Thermography. No matter if the conditions are warm or cool within a building, air movement will typically always show as very cool to ambient. Of course, we’re seeking moisture so unless the air is purposely warmed and pulled through a building’s envelope, it’s cooler.

Moisture is moisture… is moisture

In direct contrast to air movement, moisture is moisture. there are no false positives in a truly wet condition. Our only obstacle is locating and confirming the source, however, with moisture making this can easily be achieved.

Moisture mapping is a must with infrared thermography moisture intrusion testing

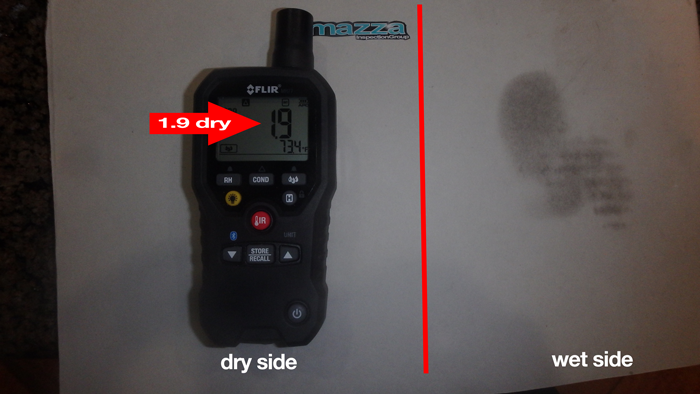

It is sufficient to say, that when we test residential plumbing issues for example, we also take moisture measurements with a moisture meter and infrared camera periodically and simultaneously throughout the evaluation. This is referred to as moisture mapping.If an anomaly is discovered, its monitor throughout the course of the evaluation with moisture mapping. For the most part, we can visually see if the affected area increases in the infrared image but is more difficult to observe with just a moisture meter alone. The time-lapse feature in the infrared camera helps with this.

The direct relationship between the color and moisture content

With most instances of moisture activity where moisture is suspect even without witnessing actually dripping, for example, you must assume the moisture is active. That said, there are, however, indications through the use of thermography which we can use to determine whether the water issue it current, active or old based on heat signatures of the thermogram. In other words, there is a direct relationship between the colors within a given pallet and the moisture content percentages. See Figure 1

The Testing

For this simple example and we’ll use a state of the art Flir moisture meter MR77, state of the art Flir T640 infrared camera, a section of the drywall, a steel bar and a sponge to illustrate my point.To begin, we will dampen the drywall with the sponge on the rear-side and allow it to soak through to the front side.

Sample 1

Sample 2

Sample 3

Sample 4

With the Testing of wallboard primarily (other materials offer different challenges), as you can see in the subject 4 that metals within wallboard materials such as metal screen material which is very common when repairing drywall patches and holes, metal corner bead and metal bullnose corner bead can read high, as a matter of fact, just as high as if the material measured was actually wet. Thus the term false positive can be applied. To rule out a false positive conclusively, one must physically view everything on the opposite side of the materials measured.

Infrared Thermography False Positive Test one

P-Trap Test With No Actual Moisture Present On The Drywall Surface But Cool Water (inside P-Trap) Test

From time to time we as thermographers will come across a condition such as this example here. This test shows how water running through a P trap will show up through the drywall. As a matter of fact, with temperature radiation be it hot or cold will show even if that surface (drywall) is not making contact with the trap.For example, this first illustration has a P-trap that is not actually touching the surface. As you can see, with the use of cooler water in the P trap, the cool temperature radiates onto the surface below it. A true-false positive.

Time-lapse example one

Time-lapse video of this condition example 1

Infrared Thermography False Positive Test Two

Actual Water Applied To Drywall Surface vs Actual Cool Water (inside P-trap) Test

Just as we see P trap false positives, we will also come across this condition as well. In this example, we will occasionally see a false positive alongside a true issue. As seen in the last frame as compared to the first, the center of the infrared thermogram is just as dark as the last frame. Many times its this false positive which leaves thermographers who do not spend the time to rule out the possibility that this is a false positive, to incorrect conclusions.Furthermore, taking a look at the first frame compared to the last, you can clearly see that after roughly 8 minutes, the P trap cooled significantly while the moisture is darkened. With this in mind, the moisture in time will also return to a cooler temperature thus a lighter thermogram, until it dries completely.

Time-lapse example two

Time-lapse video of this condition example 2

Infrared Thermography False Positive Test Three

Actual Water Applied To Drywall Surface vs Floor Hardware vs Actual Cool Water (Inside P-Trap) Test

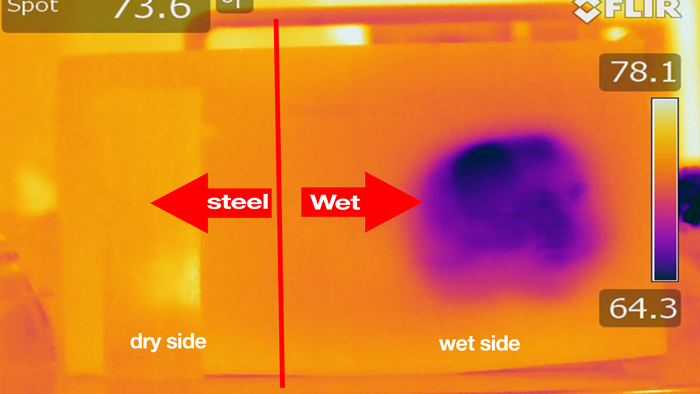

Not only does water provide false positives in thermography, so too does metal. Moreover, steel will provide two different levels of false positives.

- Cooler surface temperatures

- Incorrect surface readings with moisture meters (all meters)

When we test surfaces, we as professional thermographers will heat or cool the room in which we are conducting tests. As a matter of fact, the increased or decreased delta within this given space will create an environment most productive to thermography. Together with this conditioned ambient delta, we can see the surfaces from a completely different perspective.

Steel within the ceilings or walls (and floors) will put off a temperature signature which for all intent and purposes, looks exactly like moisture. We see this condition all the time. To effectively diagnose and rule out the possibility of a true-false positive one must understand construction basics such as framing or foundation work. Of course, without these basic understandings, it’s far easier to make mistakes in thermography.

Steel looks like water

Looking at this example below, we can see from frame one to the fourth; when the steel is cooled with compressed air it shows up in a thermogram much more vibrantly. We feel it prudent to point out the floor and ceiling cavities are typically cooler than ambient temperatures found in a home, even in the summer.

When confronted with a condition such as in example 3, professional thermographers will attempt to locate the wood framing in the ceiling/flooring example. Knowing where this framing is is crucial when ruling out framing hardware such as mending plates, hangers, straps, and bolts. Once these attaching hardware components are apparent, a thermographer can move forward in conducting a moisture intrusion investigation.

Time-lapse example three

Time-lapse video of this condition example 3

Additional Infrared Thermography False Positive Tests

Floor Joist Hardware Can Show As Cooler Heat Signature

As mentioned above, the floor or ceiling joist hardware will show as cooler, therefore, indicate a potential moisture thermographic signature. Using your basic understanding of how floors or ceilings are constructed, allows us to rule out the hardware as a non-issue easily.

Compressed Air Applied To Drywall Corner-bead (metal)

Likewise, this metal corner-beading on the edge of windows and walls will display an elevated reading in your moisture meter. The thermogram in this image will show how cool air can easily be mistaken for a leak. Additionally, if you’re testing over a metal surface as in this case, a false positive is therefore achieved.

Typical Metal Patch We See All The Time (looks like moisture heat signature)

Metal drywall patches are a nuisance for many thermographers. In an infrared image, they can show equal temperatures to ambient. In other words, it’s difficult to see them. Testing over them with a moisture meter, they will show an elevated moisture reading, a true-false positive. On the other hand, there have been cases where the hole in which these patches are intended to cover, cool the metal from the cooler cavity. This will result in a display of not only a cool surface, or False Positives in Thermography, they are in fact tested and found to be elevated on the moisture meter. A true example of a false positive.

Metal Patch vs Actual “Dry”, Non-Patched Drywall Test

In this image, we see a patch tested and then drywall not patched, tested. The readings from the moisture meter are significantly different.

Share this Post

Comments 5

As a realtor, I wish more inspectors knew about these false positives. My last inspection, we had an inspector use a thermal camera and said there were all these leaks when in fact is was just air moving into he building. Wow.. really?

I understand your frustration. The problem I see is that most inspectors are not trained in thermography and only buy the camera to compete with others who have this equipment. Oh yea, there is always that impress the agent and client factor.

Pingback: Is Infrared scanning during home inspection worth it - Thermagrapros | Los Angeles infrared inspections

Pingback: Marc Mazza Level III Infrared Thermographer - Thermagrapros

Pingback: Infrared False Positives In Home Inspection - Thermagrapros | Los Angeles infrared inspections